The Working Principle of the Fuel Dispenser Filter in Typical Fueling System

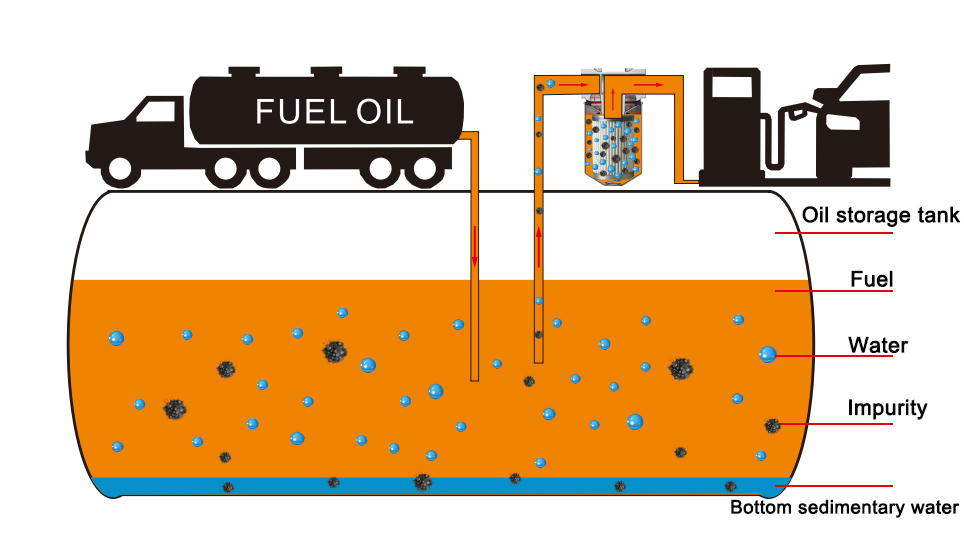

In a typical refueling system, the fuel distributor filter plays a key role. When the fuel dispenser starts, the fuel flows into the refueling system through the oil pipeline and first enters the fuel distributor filter.

The filter is equipped with multiple layers of filter screens or filter elements inside, and the pore sizes of these filter screens have been precisely designed. Larger particle impurities, such as rust, sand, and pipe debris, are intercepted by the outer coarser filter screen at the initial stage when the fuel flows through the filter and cannot continue to flow with the fuel. Smaller impurities, such as sludge, gum and some tiny metal particles, will be blocked by finer filter materials when the fuel continues to penetrate into the interior of the filter element.

After passing through multiple layers of filtration, the clean fuel flows out through the filter outlet and is then delivered to the vehicle's fuel tank via the fuel nozzle. Throughout the entire process, the filter consistently maintains a stable filtering effect. On the one hand, it prevents impurities from entering the vehicle's fuel system, avoiding problems such as clogged fuel injectors and worn fuel pumps, and ensuring the normal operation of the vehicle's engine. On the other hand, it also protects the key components in the refueling system, such as metering pumps and flow meters, reduces faults caused by impurity wear, maintains the metering accuracy and operational efficiency of the refueling system, and ensures the safe and efficient operation of the refueling process.